Why Does My Company Need

an Indoor Fall Safety Audit?

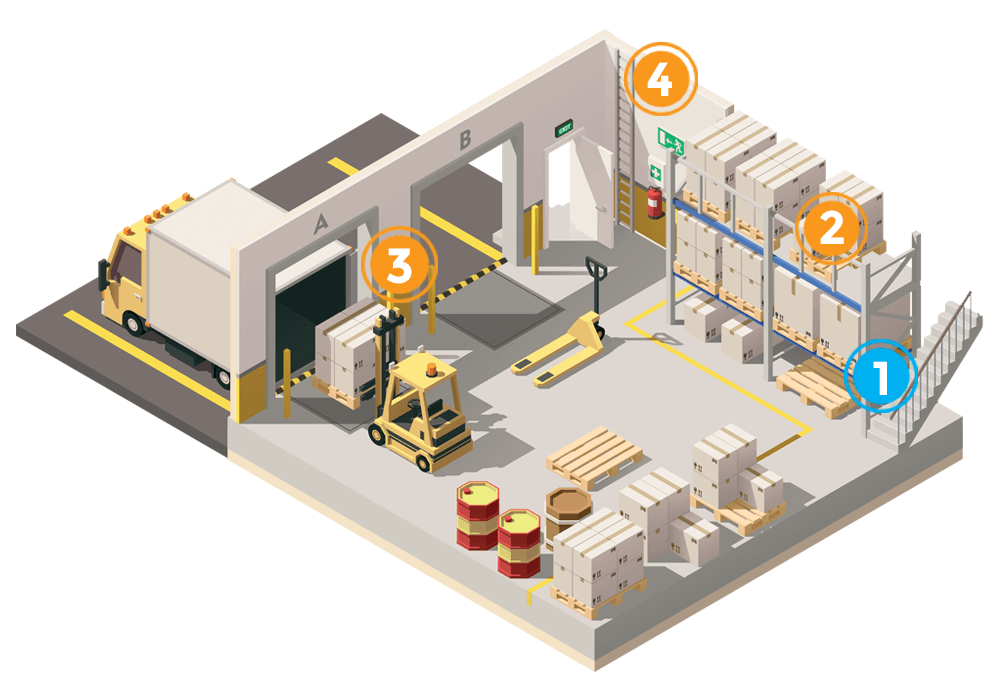

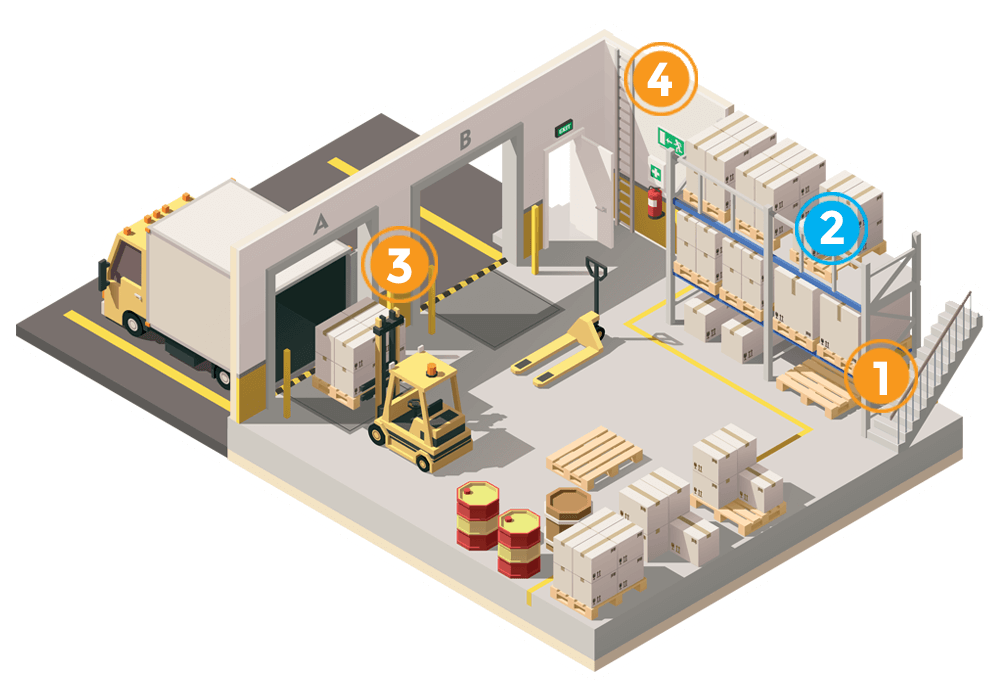

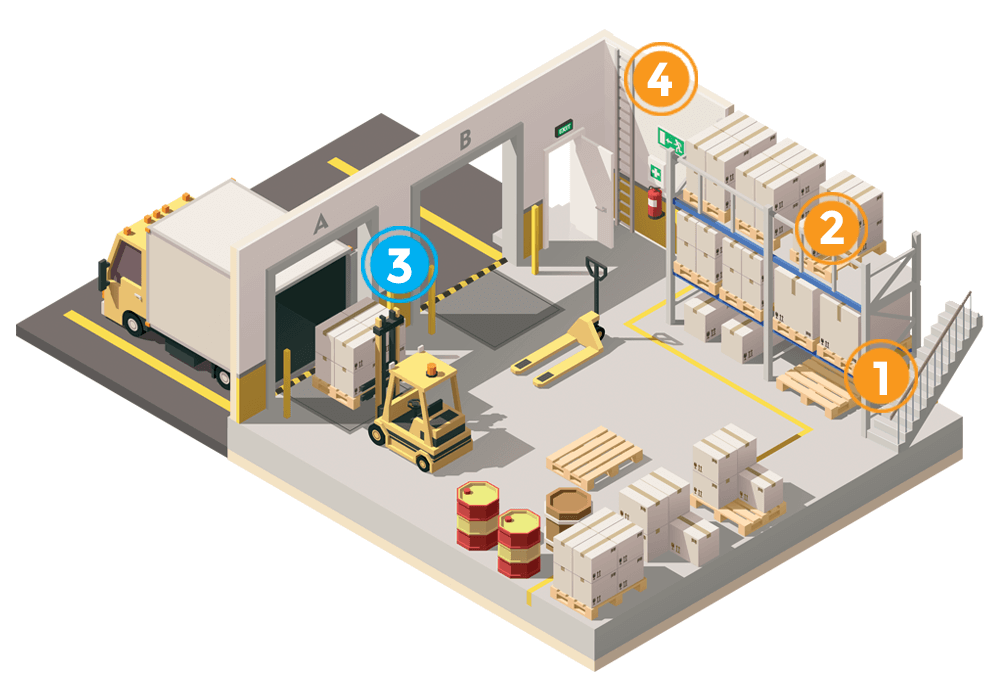

According to OSHA, falling is one of the most common causes of injuries and fatalities in the workplace. There are several areas throughout your facility that are likely to put employees, contractors, and visitors at risk of falling. So it’s important to take a closer look at these areas and make sure they are well-protected.

Falling at work is unfortunately a part of life in the workplace for many different types of facilities – from schools to manufacturing plants to pharmaceutical companies. It’s easy for even the most experienced workers to slip or lose their balance. To protect them from injury, it’s important to take a look at the latest OSHA standards and take the proper fall protection precautions in the riskiest areas in your building. This guide can help you get started.